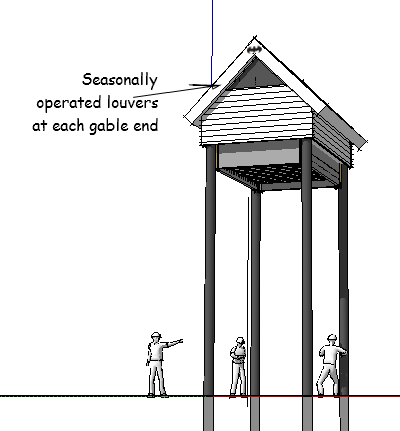

Pole

Structure

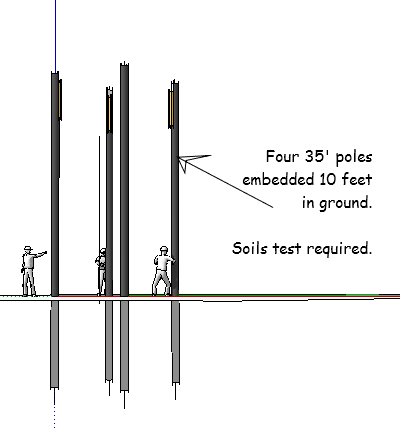

The poles

are to be embedded in compacted soil, free from moisture and

expansive clay. This is a friction bearing structure that must

be well drained. Soil tests determine depth and loading.

Alignment should be vertical

and square. All wind loads must be transmitted to the four poles

through the shear connections as a rigid four legged structure. |

|

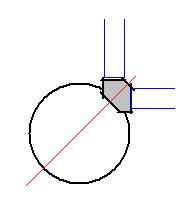

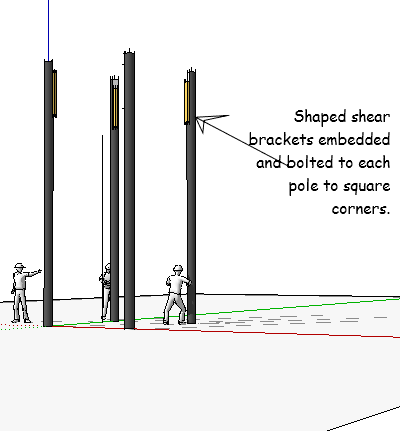

Shaped

Shear Brackets

These brackets

are shaped from clear long grain 6x, fir or glued composite.

Cut

the top of the poles so that shear the loads are embedded. Bolt

through the post at 3" end distance and 9" centers

to make the braket integral with the posts themselves.

|

|

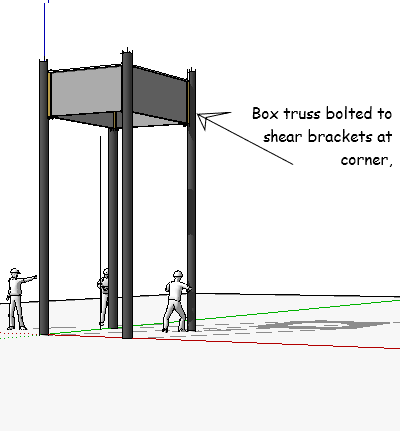

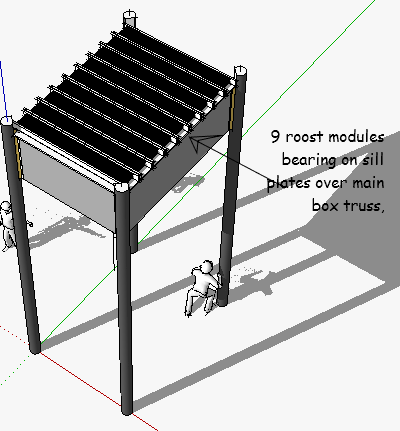

Box

Truss

The box

beam is a conventionally designed truss with plywood panel sides

structurally nailed to both sides of a 2x4 frame.

Use structural

connectors for the truss frame joints and lag bolt to the shear

brackets in the field before structurally nailing the outer

panel.

Add strap ties to inner

joints to bind the truss panels to all four sides. Connection

to the shear bracket occurs through the structural nailing and

the straps.

The result is a rigid structural

frame. |

|

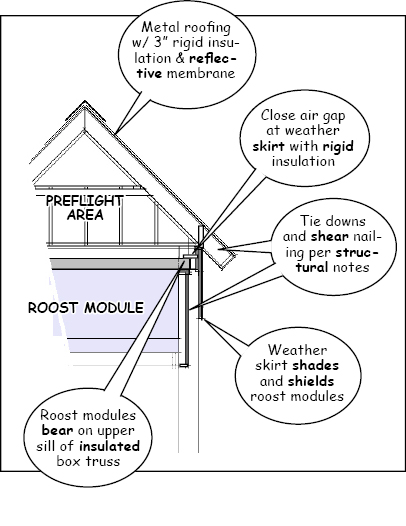

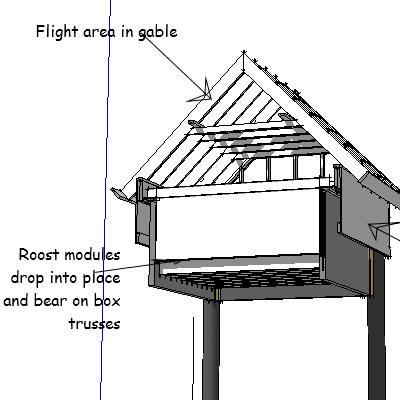

Roost

Modules

The

nine modules drop into place after the box

trusses are bolted to the piers and the weather skirt are in

place.

The roost

modules bear temporarily on the top cord of the box truss, until

the inside collar of the weather skirt is in place.

See the roost module details

S3.0 (1, 2)

of the Bat Habitat Prototypical Design by Gary Jaster, PE, dated

17 November 2008 for details and sizes.

Jaster uses 1/4" plywood

and PVC rings along a 3/8" threaded rod which may be too

fragile for Florida installation. Recommend 3/4 rod, 1/2"

plywood and 2 less vertical panels per module. |

|

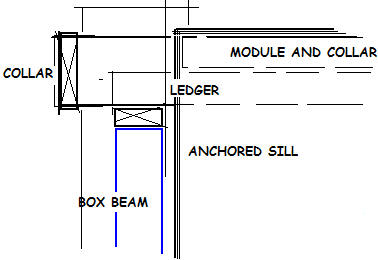

Loading

of Jaster Module

Each module

sits on a ledger running the full length of the joist that spans

the width. The joists hang from the inside collar of the weather

skirt.

Bearing

on the box beam is temporary until structural connection is

made at the roof.

Jaster01

Jaster02

|

|

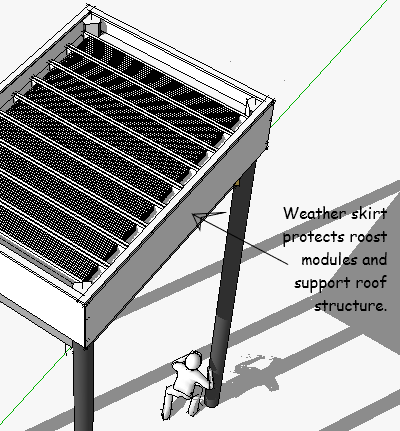

Weather

Skirt

The weather

skirt supports the roof loads and protects the roost modules.

|

|

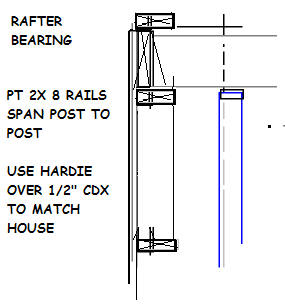

SECTION

THROUGH ROOST

The weather skirt supports

the roof structure to isolate roof loads and create an air

gap between the sides of the box truss and the roost

modules.

The idea is to cut down

on solar gain and buffer wind loads on the modules.

Note that the preflight

area and roost modules are sealed with a removeable

rigid insulation colar prior to setting the roof on

the weather skirt. |

|

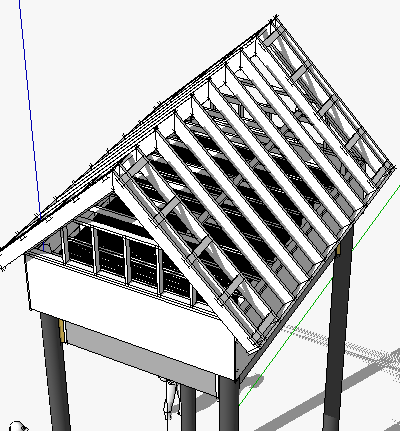

SECTION

THROUGH ROOST

The fully assembled

roof is then lifted and installed using a hinged ridge

similar to that used in modular home construction, leaving the

ridge cap to seal the joint.

Roof structure is conventionally

framed with prescriptive code tiedowns at each rafter

base and peak. All connections to be plate spliced, both

sides and structurally nailed. |

|

STRUCTURAL

NOTES

The topography

for the batt house is fully exposed with rolling

contours. Wind loads are anticipated to accelerate over

the smooth surface.

Lateral racking

from direct hurricane force winds are anticipated as the main

structural force, with relatively minimal loads

from uplift or suction.

|

|

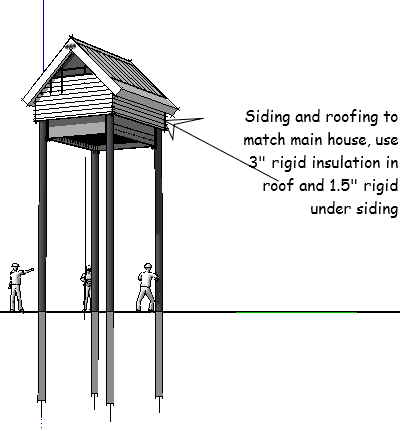

| FINISH

WORK

Elevated work

can be minimized by prefinishing materials on the ground and

completing as much assembly as possible before lifting.

Use a pinion

beam through the gable ends to rig for the lift. Weather skirts

can be field engineered to be placed as four separate panels,

with 1x4 Hardie corner boards to seal.

|

|

OPTIONS

The preflight

area, insulated panels, and seasonal ventilation require review

by batt experts since conflicting guidelines seem to be published

on the web.

See

references:

Batt

Conservatory Research

Batt

House Project

Batt

House Resource Links

Prefab

Batt Condo

Other

Batt Houses

|

|